When it comes to precision and efficiency in stone fabrication, having the right tools is paramount. Among the essential machinery for fabricators is a dedicated miter saw. For stone fabricators seeking to enhance their workflow and deliver flawless miter cuts, the Miter X 2.0 by BACA Systems offers unparalleled advantages.

In this blog post, we explore the key benefits of using a dedicated miter saw and why the Miter X 2.0 stands out as the go-to solution for stone fabrication needs.

1. Superior Cutting Accuracy

Achieving precise miter cuts is crucial in stone fabrication, particularly for applications such as countertops, showers, tub deck surrounds, and other custom stone installations. A dedicated miter saw like the Miter X 2.0 is designed specifically to produce consistent and accurate miter cuts, ensuring a perfect fit every time. With its simple design, the Miter X 2.0 minimizes errors and reduces the need for time-consuming and costly hand fabrication, ultimately saving both time and money.

2. Increased Efficiency & Productivity

In today’s competitive market, efficiency is key to staying ahead. The Miter X 2.0 streamlines the cutting process, enabling fabricators to complete jobs faster on their main cutting saw. By taking miter cuts to a dedicated saw like the Miter X 2.0, fabricators can cut 90 degree cuts on their main saw and not slow down the cutting speeds for miter cuts. As well as only make one cut separating the two adjoining miter cuts. With faster cutting speeds and minimal downtime, the Miter X 2.0 boosts overall productivity in the shop.

3. Enhanced Versatility

Stone fabrication involves working with a variety of materials, from quartzite, granite, and quartz to marble and porcelain. The Miter X 2.0 is designed to handle a wide range of stone materials, providing fabricators with the flexibility they need for diverse projects. Whether you’re creating intricate designs or tackling large-volume commercial installations, the Miter X 2.0 delivers consistent results across different materials and thicknesses.

4. Key Features of the Miter X 2.0

The Miter X 2.0 is packed with features designed to optimize the stone fabrication process:

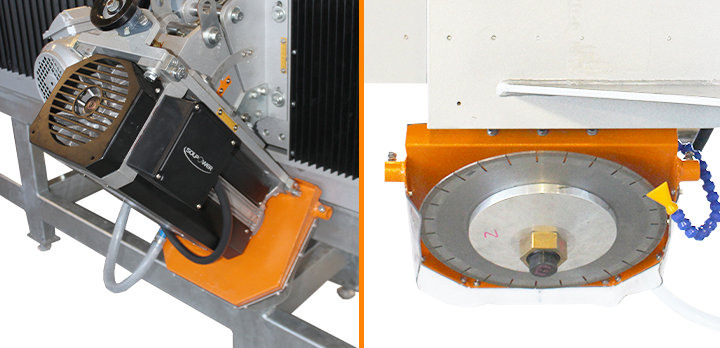

25-HP Motor With VFD

Its powerful motor can cut through the hardest materials like quartzite and Dekton with ease. It also allows for faster cutting of standard granite and quartz, improving overall efficiency.

Pneumatic Clamps

The Miter X 2.0’s clamps securely hold small parts, such as mitered aprons, in place during the cutting process to prevent movement and ensure precision.

Flat Table With Rubber Surface

The durable, rubber-coated tabletop remains flat for the machine’s lifetime and resists cuts, providing a stable working surface.

Uni-Directional Rollers

These rollers make positioning pieces against the hard stop quick and easy, reducing setup time.

Largest Cutting Stroke in the Industry

With a cutting stroke of 146 inches, the Miter X 2.0 can produce parts measuring up to 140 inches, ideal for large-scale projects.

Easy-to-Use Controls

Intuitive controls and a moveable operator control stand make the Miter X 2.0 a plug-and-play solution requiring minimal training. Operators can quickly adjust settings for accurate cuts, streamlining the workflow.

6. Durability & Reliability

BACA Systems is known for manufacturing robust and reliable machinery, and the Miter X 2.0 is no exception. Built with high-quality components and precision engineering, this dedicated miter saw is designed to withstand the demands of daily use in busy fabrication shops. With proper maintenance, the Miter X 2.0 delivers long-lasting performance, ensuring a solid return on investment.

Why Choose the Miter X 2.0 by BACA Systems?

At BACA Systems, we’re committed to providing fabricators with cutting-edge solutions that enhance their capabilities and profitability. The Miter X 2.0 exemplifies this commitment, combining advanced technology, efficiency, and precision in one powerful machine. With the Miter X 2.0, fabricators can take on more complex projects, reduce costs, and improve customer satisfaction with stunning results.

See the Miter X 2.0 in Action

Investing in a dedicated miter saw is a game-changer for stone fabricators. With its superior accuracy, efficiency, and versatility, the Miter X 2.0 by BACA Systems offers unmatched advantages that help businesses thrive in a competitive industry. Ready to elevate your fabrication shop? Contact BACA Systems today to learn more about the Miter X 2.0 and how it can transform your workflow.