Paladin CNC Router

CNC ROUTER

Paladin CNC Router

CNC ROUTER

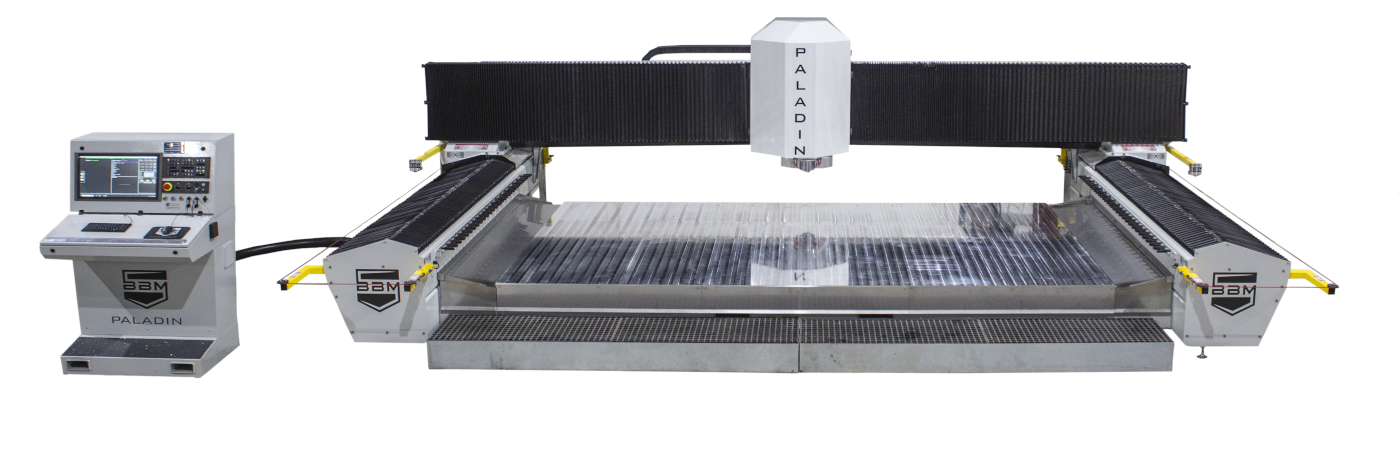

The Paladin is a large, open format, 3-axis, high-rail gantry stone milling machine. The system is designed as a wash-down machine that comes in two table sizes: 8’ X 14’ or 8’ x 16’.

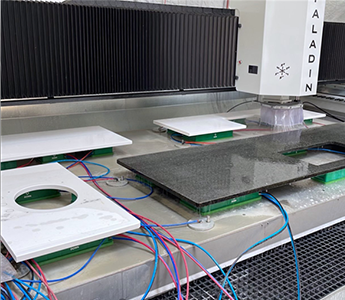

For rapid and effective polishing, there's no better choice than the Paladin. Its substantial, heavy-duty table provides the flexibility to load it with a full array of materials, start the process, and then walk away, confident that it will expertly finish countertops, vanities, and various other surfaces.

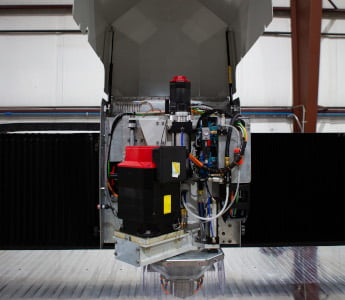

20-HP Spindle

24,000 LB MONOBLOCK

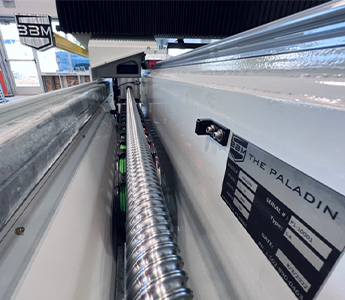

BALL SCREW