Absolutely! A 3-axis CNC router is fully capable of cutting marble, as well as other countertop materials like granite, quartz, and quartzite. Its precision and versatility make it ideal for milling for sink cut outs, custom edge profiling, polishing of edge details, and other custom shapes in a variety of stone types.

Tooling for CNC Routers

CNC tooling for processing stone countertops is essential for achieving precise and efficient cuts, shapes, and finishes. These specialized tools, including various bits and blades, are designed to handle the hardness and abrasiveness of stone materials like granite, marble, and quartz. By utilizing the right CNC tooling, fabricators can ensure smooth, accurate cuts and detailed designs, enhancing the overall quality of the finished countertops. The choice of tooling directly impacts the machine’s performance, cutting speed, and the final surface quality, making it crucial to select high-quality, durable tools suited to the specific needs of stone processing.

Thickness Limitations

Thickness limitations for stone countertops are largely determined by the type of CNC router and CNC tooling being used. Different CNC Routers and tools have varying capacities for cutting through stone, with some designed for thicker materials and others suited for thinner slices. The router’s power, the tooling’s durability, and the machine’s overall specifications play a crucial role in determining how thick the stone can be processed effectively. Selecting the appropriate equipment and tooling ensures optimal performance and accuracy, accommodating the specific thickness requirements of your stone fabrication projects.

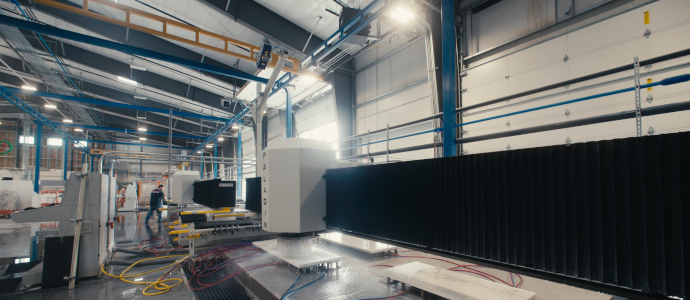

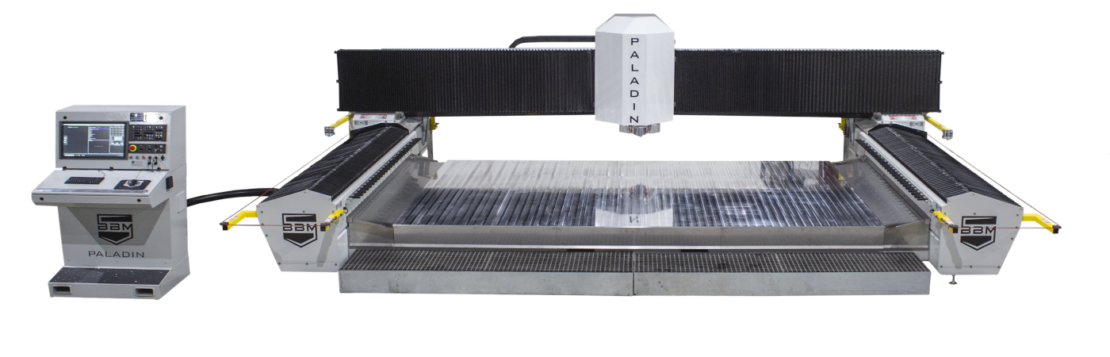

The Paladin: A Premier 3-Axis Gantry Stone Milling Machine

The Paladin is a top-tier, open-format, 3-axis high-rail gantry stone milling machine designed for efficiency and durability. Available in two spacious table sizes: 8′ x 14′ and 8′ x 16′, it excels in rapid and precise polishing, making it ideal for countertops, vanities, and fabrication requirements.

Key Features of the Paladin:

- Precision Ball Screws: Ensure long-lasting accuracy with precision ball screws that maintain high repeatability and prevent gear lashing over time, enhancing the machine’s longevity.

- Mono-Block Steel Construction: Weighing 24,000 pounds, the Paladin’s robust steel construction provides unparalleled stability and strength, ensuring optimal performance and durability.

- Largest Bearings: Equipped with industry-leading 45mm bearings, the Paladin delivers smooth operation, reduced play, and extended machine life.

- FANUC Motion Controls: Featuring globally recognized FANUC servo controllers and drives, the Paladin ensures high reliability, precision, and speed, with an impressive 52-year mean time between failures.

- Large Table Size: The 1.5” thick aluminum work surface (14′ x 8′) allows for processing large slabs in a single setup, reducing table changeovers and maximizing spindle-on time.

- AlphaCam CAD/CAM Software: Standard with AlphaCam, the Paladin offers advanced drawing and programming capabilities. Our team is ready to assist with alternative software options like Taglio or DDX.

- High-Capacity Tool Carriage: With 44 tool positions, including five full profile sets, the Paladin accommodates a wide range of tools, reducing the need for frequent tool changes.

- Easy Access to Spindle: The Z-axis tool plate cover features rubberized retention knobs and automotive supports for easy access and maintenance, protecting essential components.

- Automated Lubrication System: Standard with an automated lubrication system, the Paladin ensures consistent oil distribution to bearings and ways, minimizing user maintenance and enhancing machine longevity.

The Paladin is designed for those who demand precision, reliability, and efficiency in stone milling, making it a valuable addition to any fabrication shop.

Learn More About Our Equipment

BACA Systems is an award-winning stone equipment manufacturer that has been developing innovative fabrication equipment for over a decade. Since our founding, we’ve been committed to helping our customers improve quality, profitability, and productivity.

Please contact us today if you have questions about our stone fabrication machinery, or visit our website to learn more about our Fly to Detroit opportunity, where you can visit our shop (at our expense) to see our equipment in action.