Granite is one of the most popular materials for countertops, flooring, and custom stonework due to its unmatched durability and aesthetic appeal. However, its hardness and density can pose significant challenges for fabricators. Choosing the right CNC machine for granite cutting is essential to ensure efficiency, precision, and profitability.

At BACA Systems, we specialize in manufacturing state-of-the-art stone fabrication machinery designed to meet the unique needs of modern stone shops. Here’s an overview of our top machines for granite cutting and how they can revolutionize your workflow:

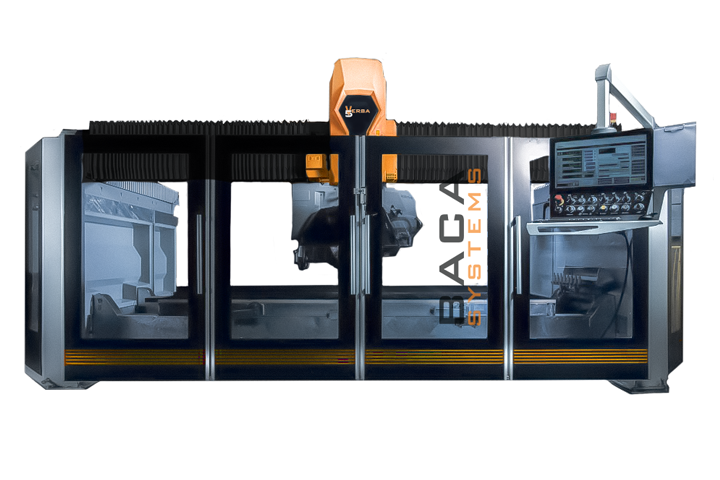

Versa 5 – CNC Saw

The Versa 5 is a versatile 5-axis CNC saw engineered for precision and efficiency. Its advanced technology allows fabricators to handle intricate cuts and unique designs with ease, making it an excellent choice for granite cutting.

Key Features

- 5-axis miter capability for creating mitered edges.

- ½ gas connection for sink cutouts, and radius cuts.

- Powerful motor to handle the density of granite effortlessly.

- Intuitive programming through DDX EasyStone

Why Choose the Versa 5 for Granite Cutting?

The Versa 5 provides unparalleled precision and flexibility, making it perfect for fabricators seeking a high-performance solution for granite projects. Its ability to handle miter cuts and complex designs streamlines the fabrication process, reducing labor and increasing productivity.

Robo SawJet M Series – Saw & Waterjet Combination Machine

The Robo SawJet M Series combines the power of a saw and a high-pressure waterjet to deliver the ultimate cutting versatility. It’s a game-changer for fabricators working with granite and other hard stones.

Key Features

- Full miter capability with both saw and waterjet.

- Integrated waterjet technology for intricate cuts, such as sink openings and curved edges.

- Dual-table design for continuous operation and maximum throughput.

- 26-HP saw motor and 50-HP waterjet pump for unmatched cutting power.

Why Choose the Robo SawJet M Series for Granite Cutting?

With its combination of saw and waterjet capabilities, the M Series offers unmatched flexibility and efficiency. It optimizes material yield by enabling tight nesting of parts and reduces the need for additional slabs, saving both time and money.

Learn more about the M Series!

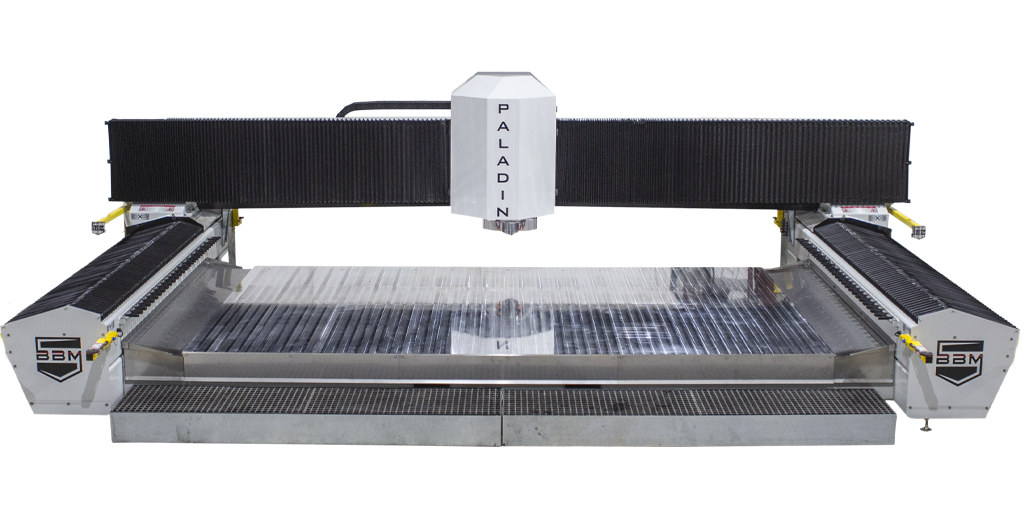

Paladin – CNC Router

The Paladin is a high-rail gantry CNC router designed for precision stone milling. Its robust construction and powerful spindle make it an ideal choice for fabricating granite countertops and custom stone projects.

Key Features

- 20-HP American-made spindle by BBM for heavy-duty performance.

- Precision ball screws for accurate and smooth motion.

- Large, open-format designed to load full kitchens.

Why Choose the Paladin for Granite Cutting?

The Paladin excels in edging, polishing, and shaping granite with high precision. Its heavy-duty design ensures reliable performance, even with the most demanding projects, while its advanced features increase efficiency and reduce cycle times.

Miter X – Dedicated Miter Machine

The Miter X is a specialized machine designed specifically for creating perfect 45-degree miters in granite and other hard stones. It delivers unmatched precision and ease of use for fabricators focused on detailed miter work.

Key Features

- Engineered for precise 45-degree miter cuts in hard materials like granite.

- Simple controls for quick and accurate operation.

- Rigid design for long-term reliability and consistent results.

Why Choose the Miter X for Granite Cutting?

If your projects frequently require mitered edges, the Miter X is an indispensable tool. It eliminates the guesswork from mitering, ensuring perfect edges every time while reducing material waste.

Why Choose BACA Systems for Granite Cutting?

At BACA Systems, we understand the challenges fabricators face when working with granite. That’s why we’ve developed a range of innovative CNC machines to help fabricators achieve unmatched precision, efficiency, and reliability. Whether you need a versatile saw, a robust router, or a combination machine with waterjet capabilities, we have the perfect solution for your shop.

Visit BACA Systems to learn more about our complete lineup of stone fabrication machinery and discover how our cutting-edge solutions can transform your granite cutting operations.