Both 5-axis saws and 5-axis sawjets are great stone cutting machines, but it may be difficult to decide which one is the better investment for your purposes.

Both styles of machines can shape non-linear cuts like sinks, arcs, radii, and faucet holes. However, a sawjet is 10 times faster for shaping non-linear cuts by using a waterjet versus an incremental bit that is step cutting/incrementally removing material. The average time to process a full sink on a waterjet is four to five minutes on 3CM material, whereas a 5-axis saw can be 20 to 30+ minutes for just one sink. Most fabricators doing any sort of volume using 5-axis saws end up cutting sinks by hand because they can cut them faster by hand than the machine can, or they add additional CNC routers because they don’t have time to use the incremental bit on the saw and only cut rectangles.

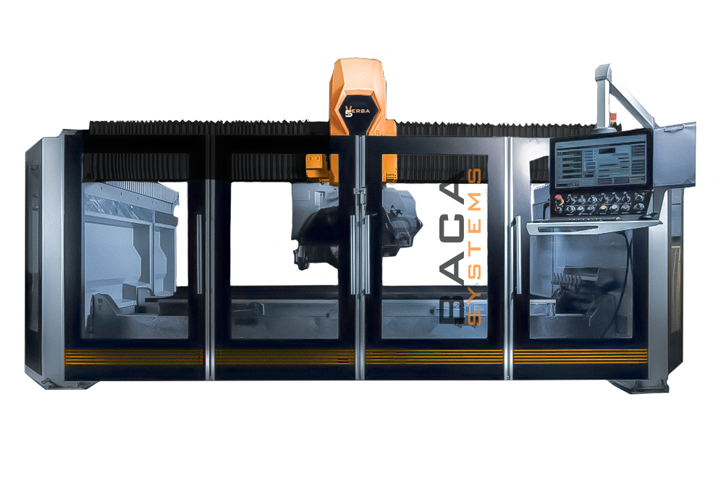

5-Axis CNC Saw

5-axis CNC saws, like BACA’s Versa 5, are highly versatile and flexible. The Versa 5, in particular, features a 5-axis interpolated cutting center designed for processing natural and engineered stone, ceramic, and ultra-compact materials. It excels in a range of slab fabrication tasks with the following features:

- Comprehensive Capabilities: The Versa 5 efficiently handles trimming, de-tensioning cuts, mitering, multi-directional and curvilinear jobs, as well as inner cut-outs, meeting high standards for speed, accuracy, working strokes, and software interface.

- Milling Processes: The Versa 5 features a standard 1/2-inch gas connection on the saw motor, designed for use with incremental bits and core bits. This connection is ideal for milling tasks, such as sinks, arcs, radii, flush-mount cooktops, and other milling processes. Additionally, the Versa 5 offers an optional side spindle called the Multi-Tool 9+1. This accessory boosts milling speeds by 55% through higher RPMs and includes automatic tool changers, reducing the need for operator intervention during milling operations.

- Robust Tilting Table: The hydraulically driven table, made from heavily ribbed steel and hot zinc-coated, measures 137.7” x 92.1,” and is built to withstand demanding stone environments.

- Automatic Saw Blade Inclination: The saw blade features powered automatic inclination, adjustable from 0 to 90 degrees, enabling quick changes in machine head angle without manual intervention. This function simplifies complex cutting cycles, speeds up operations, and reduces operator errors.

- Mechanical Touch-Probe: This probe, paired with management software, measures the material’s top surface to detect slab thickness variations, uneven table surfaces, and material warping. The Versa 5 software then automatically adjusts the saw blade trajectory to ensure accurate miters and dimensionally correct parts.

- Automatic Saw & Tool Wear Sensor: Equipped with management software, this sensor detects saw blade diameter and tool length, automatically adjusting the cutting tool’s depth. It ensures precise cutting through the material and minimizes manual adjustments, enhancing the cutting table’s longevity.

5-Axis Sawjet

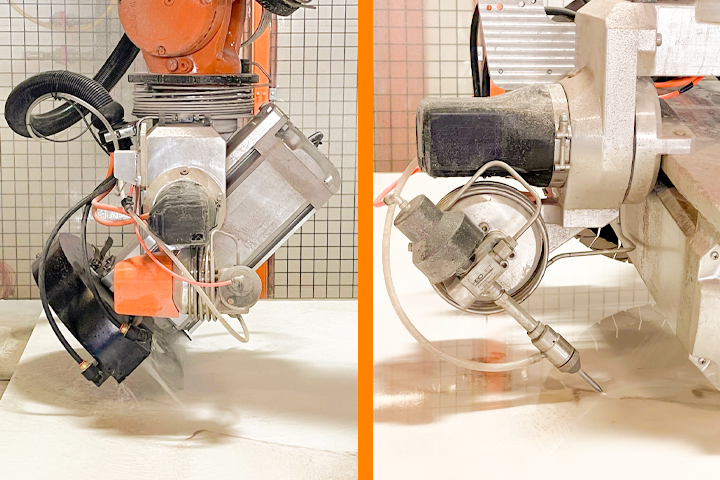

5-axis sawjets, like our M Series, are versatile cutting machines that combine sawblade and waterjet mitering in one unit, efficiently handling large slabs. Here’s a simplified overview of our M Series and its features:

- Saw & Waterjet Mitering: M Series offers both saw and waterjet mitering for various tasks, including precise cuts for inside corners, integrated sinks, and customized countertops. The saw handles straight cuts faster and cheaper, while the waterjet is used for complex, non-linear cuts, reducing material waste.

- Reliable & Low Maintenance: This model features a robust KUKA KR 210 robot with a 26-HP saw motor and a 50-HP waterjet. Known for reliability and precision, the robot requires minimal maintenance—just occasional greasing and oil changes. The waterjet design simplifies upkeep with easily accessible lines.

- Boost CNC Router Output: Pre-shaping non-linear cuts with the M Series can increase CNC router output by 30%. This allows the CNC router to focus on edge and polish, optimizing overall production efficiency.

- Efficient Programming: The M Series utilizes Alphacam software with BACA’s custom toolbar for easy and precise programming, including multi-point slab thickness adjustment and a unique auto-calibration process.

- Upgradeability: You can upgrade from a single-table to a dual-table setup, potentially doubling production. This flexibility allows for future growth without the need to replace machinery.

- Small Footprint: This model maintains a smaller footprint compared to competitive bridge-based machines, saving valuable space and reducing real estate costs.

- 3-Sided Access: The M Series features low-profile tanks accessible from three sides, improving convenience and eliminating the need for operators to climb onto the table to reach pieces.

Cost Considerations

Typically, a 5-axis CNC saw costs about half as much as a 5-axis sawjet. While both machines can handle non-linear cuts like sinks, the sawjet is much faster due to its waterjet capabilities. The waterjet also conserves 10 to 20% more material by eliminating blade overtravel and finishing precisely to a defined point. Additionally, it offers greater flexibility for intricate tasks, such as integrated sinks. Overall, both 5-axis saws and 5-axis sawjets are excellent choices for countertop fabrication, each with its own advantages.

Learn More About BACA’s Fly to Detroit Program

Still not sure which option is best for your needs? Fly out to Detroit and see the Versa 5 and M Series in action.

BACA Systems will fly potential customers to our headquarters in Lake Orion, MI, with no obligation to purchase. We strongly encourage all fabricators to visit BACA to thoroughly investigate our machinery solutions to see if they are the right fit for your company. The trip to BACA Systems is typically one day, depending on direct flights. In this program, in just one business day you’ll see live machine demonstrations, where you’ll learn more about our software, machine capabilities, and any required maintenance, as well as visit a few local fabrications shops in Michigan using our equipment.

Fly to Detroit soon, and let us show you how to reduce your material and labor costs, complete projects up to four times faster, and boost your profit margins. Or, contact us today with questions or to request a quote.