General Benefits of Using a Waterjet in Your Stone Fabrication Business

Increases Material Yield by 10 to 20%

BACA Systems’ Robo SawJet & Robo SawJet M Series leverage advanced waterjet technology to eliminate blade overtravel, enabling more countertops to be cut out of each slab. This Tetris-like cutting method ensures optimal slab utilization, helping fabricators maximize yield and reduce waste. By eliminating blade overtravel, you can produce the highest number of countertop parts from each slab or bundle. Additionally, when smaller parts are needed but don’t fit on the initial slab(s), the precision of the waterjet minimizes the need to purchase additional slabs—saving both time and money.

Saves 3 to 4 Hours of Labor Per Slab

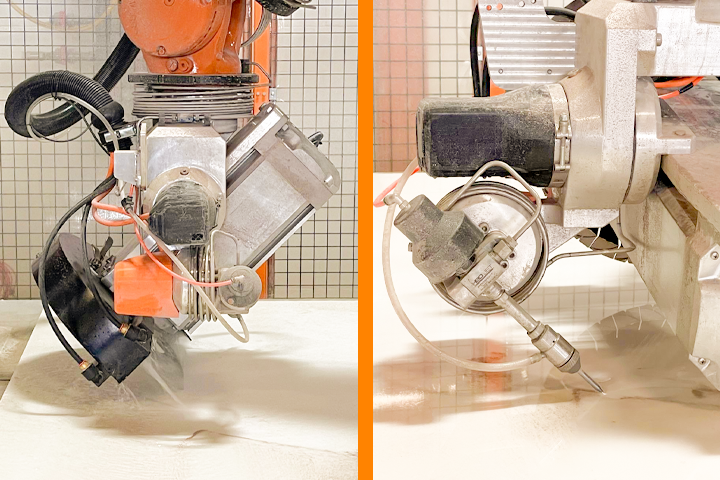

The Robo SawJet and Robo SawJet M Series combine a powerful 26-HP saw motor with a 50-HP waterjet to deliver unmatched precision for intricate cuts. The 50-HP waterjet effortlessly handles non-linear cuts like sinks, arcs, and radii during the sawing process. Pre-shaping these curved cuts during sawing reduces downstream labor requirements and or shortens the cycle time of CNC routers. This streamlined process saves fabricators 3 to 4 hours of labor per slab while enhancing overall efficiency.

Increases CNC Router Output by 30%

Fabricators utilizing CNC routers can achieve a 30% increase in output by leveraging the Robo SawJet or Robo SawJet M Series for pre-shaping non-linear cuts, such as sinks and arcs. The waterjet technology allows CNC routers to focus exclusively on edging and polishing, improving both speed and productivity. Dual-table SawJet systems, like the M Series, are capable of feeding 3 to 4 CNC routers, making it essential for optimizing CNC router capacity. Additionally, this approach extends the lifespan of CNC router spindles by eliminating the side-load stress associated with sink shaping, reducing maintenance costs and ensuring long-term efficiency.

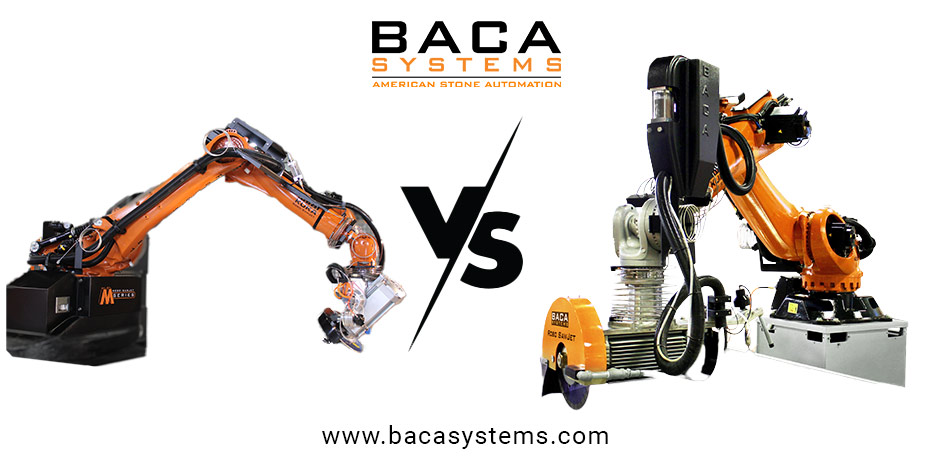

Robo SawJet M Series

The M Series from BACA Systems is the ultimate cutting solution for fabricators seeking advanced technology and unparalleled efficiency. Designed to streamline the stone fabrication process, this innovative machine offers full mitering capabilities in a single, powerful unit, seamlessly integrating both sawblade and waterjet mitering.

Why Choose the M Series?

- Unmatched Performance for Super Jumbo Slabs: Equipped with a generous saw and waterjet mitering envelope, the M Series effortlessly tackles super jumbo slabs, enabling fabricators to handle even the most demanding projects with ease. Whether working with intricate cuts or larger dimensions, the M Series delivers precise results every time.

- Simplified & Precise Programming With Alphacam: Programming the M Series is both easy and efficient, thanks to its integration with Alphacam software and BACA Systems’ custom toolbar. This advanced solution enables precise multi-point slab thickness adjustment for mitering, reducing setup time and enhancing cutting accuracy.

- Patent-Pending Auto-Calibration for Superior Results: One of the M Series’ standout features is its patent-pending auto-calibration process, which ensures consistent and precise performance across every project. This groundbreaking innovation minimizes errors and maximizes productivity, setting the M Series apart as a leader in stone fabrication technology.

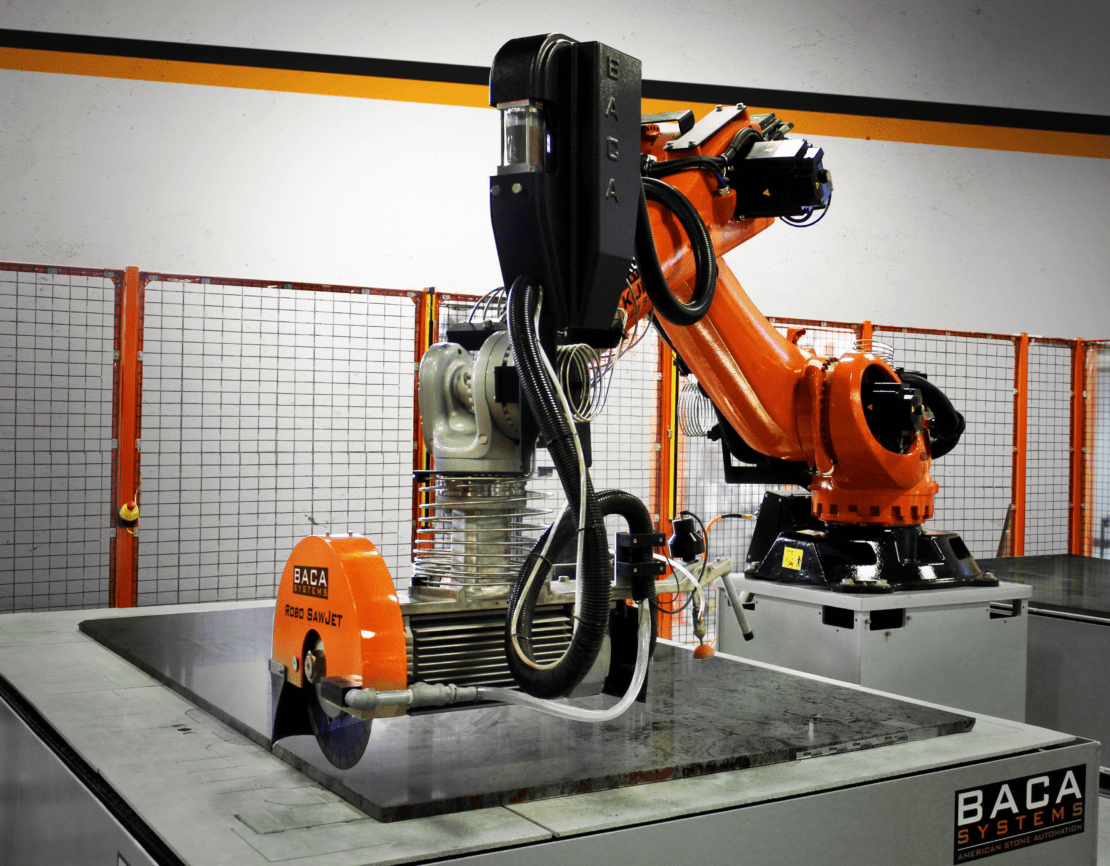

Robo SawJet

The Robo SawJet 2.0 from BACA Systems is the next generation in precision cutting technology, combining unmatched efficiency, cutting-edge automation, and innovative features to revolutionize the stone fabrication industry. Designed to maximize productivity and reduce waste, this state-of-the-art machine integrates a high-powered saw motor with advanced waterjet technology for seamless and versatile cutting solutions.

Why Choose the Robo SawJet 2.0?

- Features Powerful Cutting With Unmatched Precision: Equipped with a robust 26-HP saw motor and a 50-HP waterjet, the Robo SawJet 2.0 delivers exceptional power and precision for a wide range of applications. From straight-line cuts to intricate, non-linear designs like sinks, arcs, and radii, this machine ensures every cut is clean, accurate, and ready for finishing.

- Optimizes Material Yield & Reduce Waste: The Robo SawJet 2.0 is engineered to maximize material utilization by minimizing blade overtravel and enabling tight nesting of parts. This Tetris-style cutting approach optimizes every slab, increasing material yield by 10 to 20%. By reducing the need for additional slabs, fabricators save time, materials, and costs on every project.

- Saves Time & Labor: This innovative machine is designed to streamline the fabrication process, saving fabricators 3 to 4 hours of labor per slab. By pre-shaping non-linear cuts during the sawing process, the Robo SawJet 2.0 significantly reduces downstream labor and allows CNC routers to focus on edging and polishing, boosting overall efficiency.

- Extends CNC Router Life & Boosts Productivity: Pre-shaping non-linear cuts with the Robo SawJet 2.0 not only enhances efficiency but also extends the lifespan of CNC router spindles. By eliminating side-load stress during shaping, fabricators reduce maintenance costs and ensure longer-lasting performance. By pre-shaping non-linear cuts on a SawJet machine, fabricators will realize 30% more output per CNC router.

Why Choose BACA Systems?

BACA Systems is your trusted partner in stone fabrication machinery. We don’t just manufacture industry-leading machines; we provide comprehensive installation, service, and ongoing support to ensure your success. Explore how the Robo SawJet or Robo SawJet M Series can transform your fabrication processes and maximize your operational efficiency. Contact us today for more information!