Types of Granite Cutting Machines

Stone cutting products are used in a range of residential and commercial applications. Cutting through granite, marble, quartz, and ultra-compact materials requires precision and speed. BACA Systems provides automated fabrication solutions for stone countertop fabricators of all different sizes.

Explore the features of BACA Systems’ granite saw machines to see how you can increase productivity, reduce labor, and increase material yield in your stone manufacturing process. All BACA machines are designed to increase profitability and production safety.

Robo SawJet

Learn more about the robotic sawjet that started it all. The Robo SawJet was the original robotic model produced by BACA Systems, and it continues to deliver reliable operations and superior cutting flexibility.

Explore the primary features that help this granite saw machine outperform the competition:

- High Reliability & Minimal Maintenance

- Increase Material Yield by 10 to 20%

- Reduce Labor by 3 to 4 Hours (per slab)

- Increase CNC Router Output by 30%

- Upgradeability to Dual Table

- Smallest 2 Table Footprint

- 3 Sides of Access

The Robo SawJet is our programmable Saw and Abrasive WaterJet cutting system. Robo SawJet combines traditional stone processing technology with lean industrial machine technologies to provide an affordable and reliable system for your cutting operations.

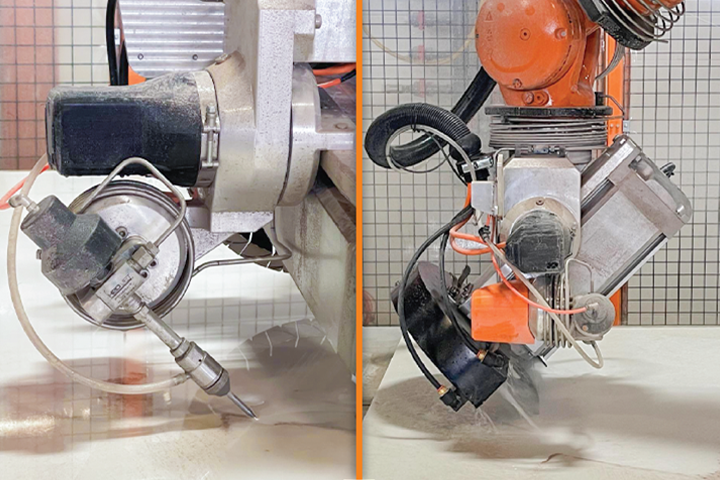

Robo SawJet utilizes a KUKA robot equipped with the simplicity of a conventional saw in combination with the flexibility of abrasive waterjet technology.

The system features BACA’s Easy-2-Use, Ready-2-Use programming software and an intuitive operator interface to automatically generate cutting paths with a few clicks of the mouse. Programming can be accomplished at the machine on the factory floor or in the office remotely. The system also uses less floor space than traditional gantry or bridge style machines.

Robo Sawjet M Series

The M Series is an advanced cutting machine that offers full mitering capabilities in a single unit, accommodating both sawblade and waterjet mitering.

Here are the of the advantages of choosing a M Series:

- Full Mitering Capability

- High Reliability & Minimal Maintenance

- Increase Material Yield by 10 to 20%

- Reduce Labor by 3 to 4 Hours (per slab)

- Increase CNC Router Output by 30%

- Upgradeability to Dual Table

- Smallest 2 Table Footprint

- 3 Sides of Access

With cutting and mitering capability using both the saw and abrasive waterjet, the M Series combines traditional stone processing technology with lean industrial machine technologies allowing you to cut and miter slabs in one process. At its core, the Robo SawJet M Series utilizes a KUKA robot in combination with the flexibility of abrasive waterjet technology to provide the most reliable cutting machine today.

Adding a Robo SawJet M Series to your fabrication process is the No. 1 way to increase profitability by reducing material cost by 20% through maximizing slab yield.

In addition, Robo SawJet M Series reduces the amount of downstream processing by reducing up to 4 hours of work on every slab by completing all arc cuts, radius cuts, sink openings, and faucet holes during the sawing process.

You can let the sawjet process complete 90% of your countertop fabrication by cutting your pieces completely, including sinks, faucet holds, arcs, and radius. This leaves only edge shaping, polishing, and/or gluing of mitered pieces to be completed downstream.

Paladin CNC Router

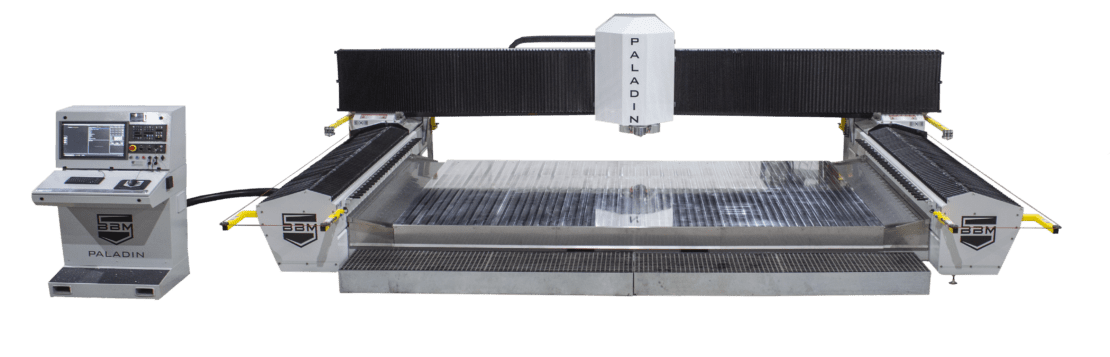

The Paladin is a large, open format, 3-axis, high-rail gantry stone milling machine. The system is designed as a wash-down machine that comes in two table sizes: 8’ x 14’ or 8’ x 16’.

Here are some of the key advantages of the Paladin over competitive machines:

- American-Made

- Precision Ball Screws

- Largest Bearings

- FANUC Motion Controls

- Large Table Size

- High-Capacity Tool Carriage

- 24,000-lb Monoblock Machine

Equipped with a 20-HP spindle for rapid and effective polishing, there’s no better choice than the Paladin.

Its substantial, heavy-duty table provides the flexibility to load it with a full array of materials, start the process, and then walk away, confident that it will expertly finish countertops, vanities, and various other surfaces.

Miter X

Create custom built-up edges and other luxurious mitered countertops with the Miter X. If you’re crafting waterfall islands or other designer products, this granite cutting machine is a foundational piece of equipment for your granite shop.

Consider the following specifications of the Miter X compared to other dedicated miter saws:

- Largest Saw Motor in Class at 25 HP w/VFD

- Galvanized Base

- Largest Cutting Stroke at 140″

- Siemens Controls

- Moveable Operator Controls

- Clamps to Hold Down Small Pieces

The Miter X 2.0 is equipped with a 25-HP saw motor, making it the most powerful miter saw in its class.

The stronger motor allows for faster processing speeds on all countertop materials and provides the power required to cut the hardest materials, such as quartzite, with ease.

With over 250 machines installed in North America, the Miter X is the right solution for your miter needs.

Stone Fabrication & CNC Stone Machining

This machining process uses computer-automated tooling to cut, shape, edge, polish and engrave a variety of stone materials. It’s essential to choose the right equipment for your stone manufacturing application.

Start with a digital template/design of the project you wish to create hard surfaces for in your machining process.

Every CNC machine has various cutting procedures and angles that it’s capable of achieving. When you select the optimal equipment for your process, there’s few limitations to the manufacturing processes you can achieve through CNC machining.

Before you work with a stone cutting saw or granite cutting machine, consider the available applications for these products. CNC stone processing allows you to work with these materials:

· Granite, Marble, & Quartzite

· Quartz and Other Man-Made Materials

· Slate, Soapstone, Limestone & Many Other Natural Stones

· Ultra-Compact & Porcelain Materials

· Other stone products

Create innovative components for commercial and residential use. A stone cutting machine from BACA Systems can take slabs of these materials to manufacture the following components:

· Countertops

· Vertical Applications like showers & walls

· Coffee tables & other stone furniture

· Island counters

· Bathroom vanities & tub deck surrounds

· Decorative slabs

· Many other hard surface applications

Consider the angles, cutouts and other processing steps you need to take to make your final product. Some BACA Systems machines are capable of start-to-finish stone processing, while others offer high-speed processing, but handle a more narrowly defined part of the overall fabrication process.