Quartzite has become one of the most sought-after natural stones for modern countertops due to its unique beauty and durability. However, its extreme hardness presents a significant challenge for fabricators, requiring specialized tools and techniques to cut and shape it efficiently.

For fabricators looking to process quartzite countertops with precision and speed, it’s crucial to focus on several factors:

- Saw Motor Strength: A powerful saw motor is essential for cutting through quartzite’s dense composition.

- Adequate Water Supply: Proper cooling and lubrication are critical to maintain blade performance and prevent overheating.

- High-Quality Saw Blade: Durable, sharp blades designed for quartzite are vital for smooth, clean cuts.

- Machine Rigidity: A rigid machine structure ensures stability and accuracy during the cutting process.

- Advanced Technology: Utilizing the latest CNC and robotic cutting systems can dramatically improve efficiency.

At BACA Systems, we provide cutting-edge machinery specifically designed to meet the demands of fabricating hard stones like quartzite. Here are our top recommended products for cutting quartzite, along with how they help fabricators succeed:

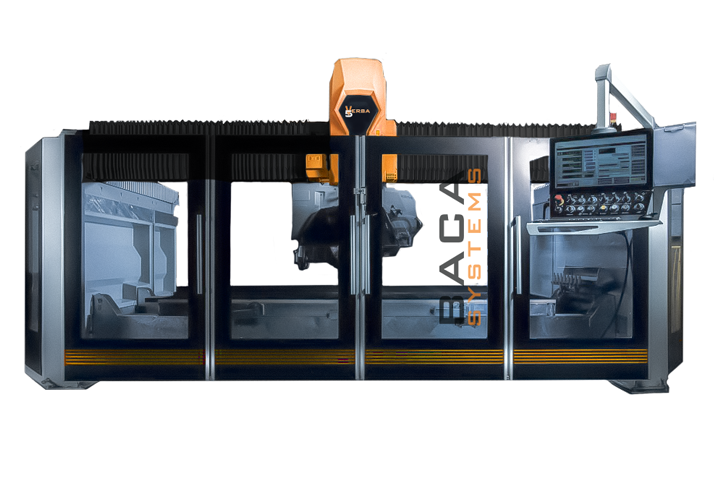

Versa 5 – CNC Saw

The Versa 5 is a versatile 5-axis CNC saw that excels at cutting and shaping hard materials like quartzite. With its powerful saw motor and precision controls, the Versa 5 allows fabricators to perform complex miter cuts, sink openings, and radius edges effortlessly.

Key Benefits:

- Robust Saw Motor: The powerful saw motor ensures smooth, precise cuts through quartzite.

- CNC Controls: Intuitive CNC controls make it easy to program intricate designs.

- Advanced Software: Advanced software integration simplifies production while reducing operator error.

Ideal Applications: Perfect for shops seeking a flexible solution for custom countertop designs or high-precision cuts in tough materials.

M Series – Saw & Waterjet Combination Machine

The M Series combines a powerful saw with high-pressure waterjet cutting technology, providing unmatched versatility and efficiency for quartzite fabrication. Its dual-table design enables continuous operation, reducing downtime and boosting throughput.

Key Benefits:

- Waterjet Technology: The integration of waterjet technology eliminates overcuts and enables tight nesting for optimal slab utilization.

- Powerful Pump: A 50-HP waterjet pump delivers high-pressure performance to handle intricate cuts like sink openings and non-linear shapes.

- Durable Design: The M Series is built with a rigid structure for superior accuracy and durability.

Ideal Applications: Best for fabricators looking to optimize material yield and process both straight and complex cuts in a single machine.

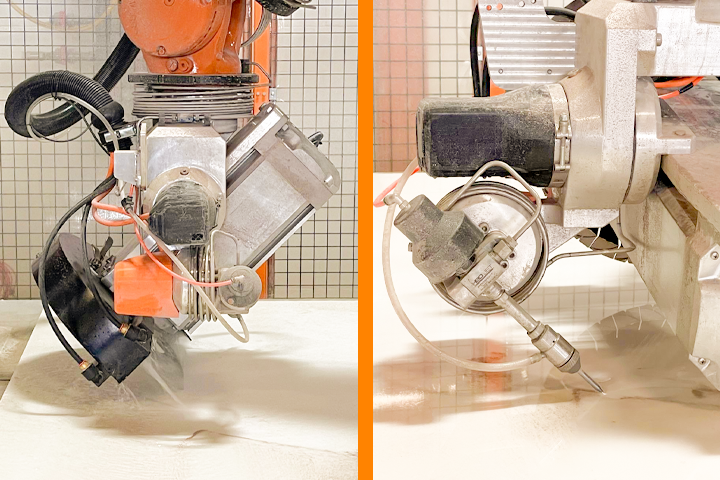

Robo SawJet – Robotic Saw & Waterjet System

The Robo SawJet is a revolutionary robotic cutting system designed to handle the toughest materials, including quartzite. Combining the precision of a 26-HP saw motor with the versatility of a 50-HP waterjet, the Robo SawJet provides fabricators with a seamless solution for cutting complex countertop parts.

Key Benefits:

- Automated: Robotic automation ensures consistent performance and repeatability.

- Waterjet Technology: The waterjet minimizes material waste by enabling tighter nesting of parts.

- Speed: High-speed operation significantly reduces production time for large jobs.

Ideal Applications: Perfect for high-volume shops looking to increase productivity and minimize labor costs.

Miter X – Dedicated Mitering Solution

The Miter X is a dedicated mitering solution designed to make precise 45-degree cuts in quartzite and other hard materials. This machine’s accuracy and ease of use make it indispensable for fabricators working with intricate designs or mitered edges.

Key Benefits:

- Dedicated Design: The Miter X is engineered for perfect 45-degree miters in even the hardest materials.

- Easy to Use: Its simple operation reduces training time and increases shop efficiency.

- Durability: Its exceptional build quality ensures reliable performance for years.

Ideal Applications: A must-have for creating seamless mitered edges on quartzite countertops.

Why Choose BACA Systems for Cutting Quartzite?

At BACA Systems, we understand the challenges fabricators face when working with quartzite and other hard materials. That’s why we design our machines with advanced features, powerful motors, and robust construction to deliver unmatched performance and reliability.

Explore our complete range of stone fabrication machinery and discover how our innovative solutions can take your shop’s quartzite fabrication to the next level.