A Scalable Robot with with Optimized Processing Time

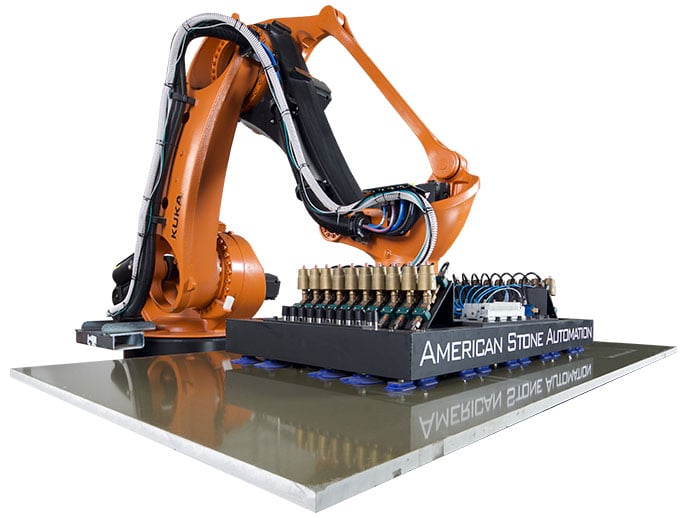

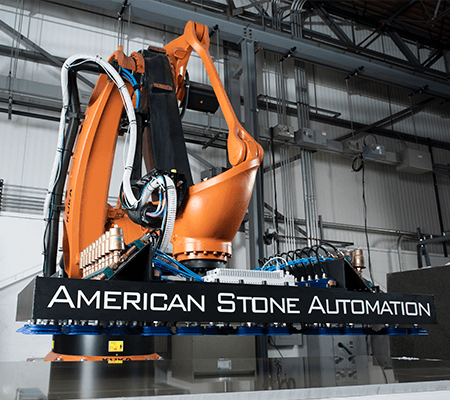

High payload KUKA robot equipped with a smart vacuum tool capable of handling several shapes and sizes of uncut and cut stone. The robot can be integrated with a linear positioning track to provide a large range of motion Moves the material from station to station with fast traverse times for maximum throughput.

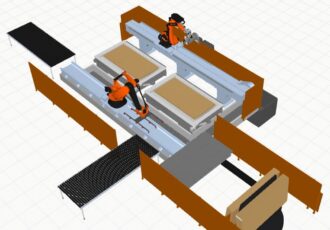

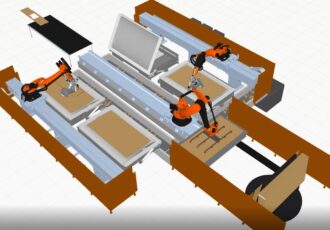

Because Robo Lift is scalable, it can be configured with a single station or multiple “cells”. Allows for several sawjet stations or a combination of sawing and CNC machining stations to be serviced by a single Robo Lift robot. Incoming staging allows slabs to be pre-loaded for several hours of production.

Robo Lift is always available for immediate unloading and reloading of the work table. Labor cost is also significantly decreased, allowing headcount to be reduced by several operators per shift which results in a safer work environment for operators, while reducing the potential for material damage that may occur while moving the material manually.