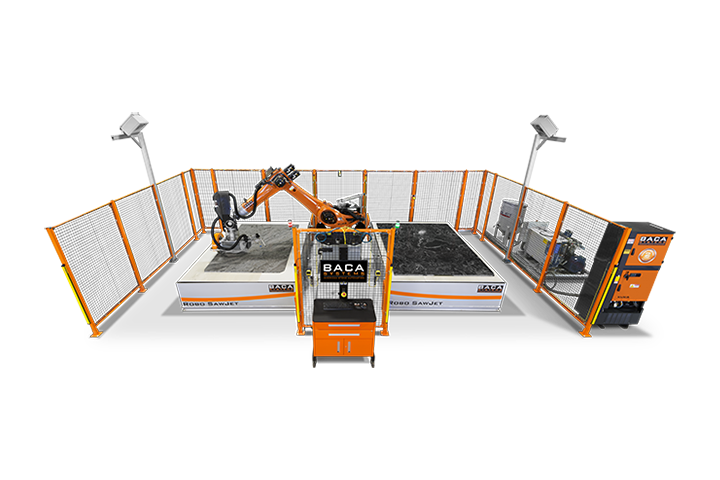

Robo Sawjet 2.0

Robotic SawJet

Robo Sawjet 2.0

Robotic SawJet

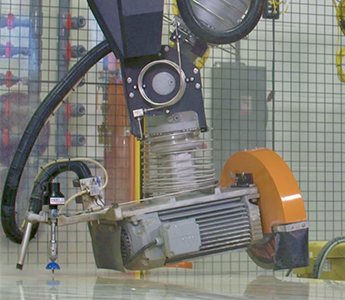

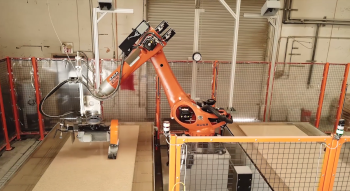

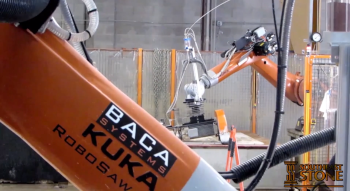

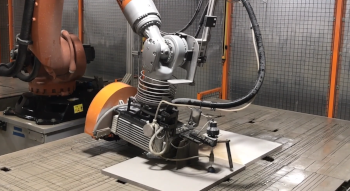

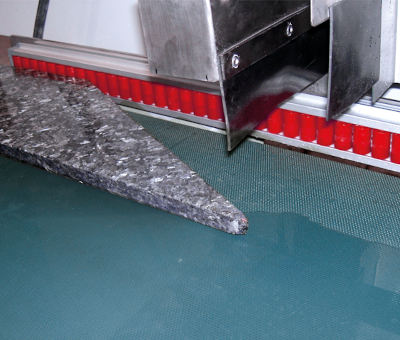

The Robo SawJet was the first-ever robotic sawjet introduced to the stone fabrication industry, revolutionizing the way fabricators cut stone. Unlike traditional bridge saws, which require frequent maintenance and part replacements, the Robo SawJet delivers greater reliability, precision, and efficiency. Today, BACA Systems has over 650 Robo SawJets operating in stone fabrication shops across North America, helping businesses increase productivity while reducing downtime and maintenance costs.

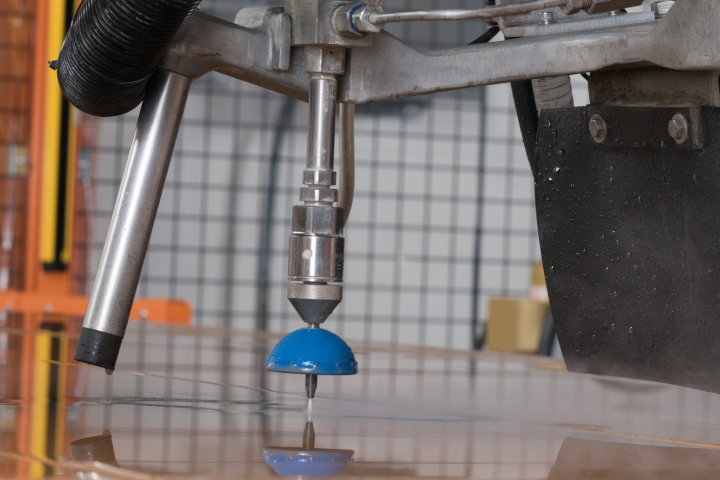

Minimal maintenance

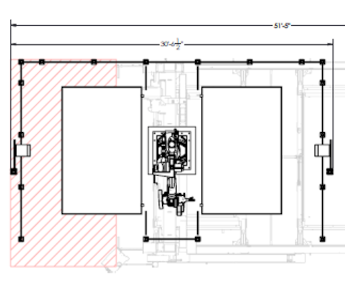

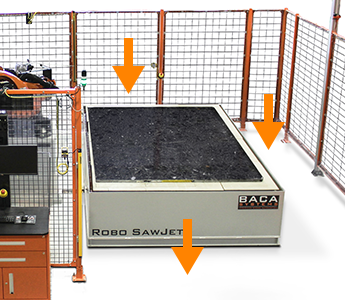

Small

footprint

footprint

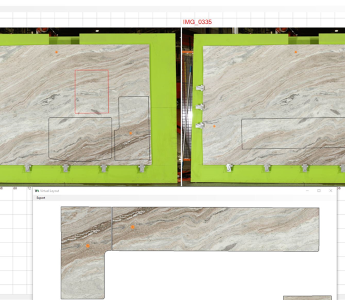

PC-based software