Stone CNC routers and waterjet cutting machines are both powerful, precise, and efficient tools for stone cutting applications. But, despite their similar uses, each machine has its advantages and disadvantages.

If you’re looking for guidance on whether to purchase a stone CNC machine or a waterjet cutting machine, you’re in the right place.

In this article, we’ll compare and contrast these two powerhouses and provide helpful tips on how to find the best machinery for your stone cutting operations.

What Is a Stone CNC Router?

A 3-axis stone CNC router, like the Paladin, is a powerful tool designed for precise cutting, shaping, and milling of stone materials. This machine operates on three axes—X, Y, and Z—allowing it to move and manipulate stone with high accuracy. Key benefits include its ability to create intricate designs and detailed patterns, making it ideal for custom countertops, tiles, and architectural features. A 3-axis CNC router also enhances efficiency by automating complex tasks, reducing manual labor and minimizing errors. Its precision ensures consistent results and high-quality finishes, while its versatility allows for the handling of various stone types and thicknesses. Investing in a 3-axis stone CNC router boosts productivity, improves craftsmanship, and supports scalable stone fabrication projects, making it an essential asset for modern stone working businesses.

What Is a Waterjet Machine?

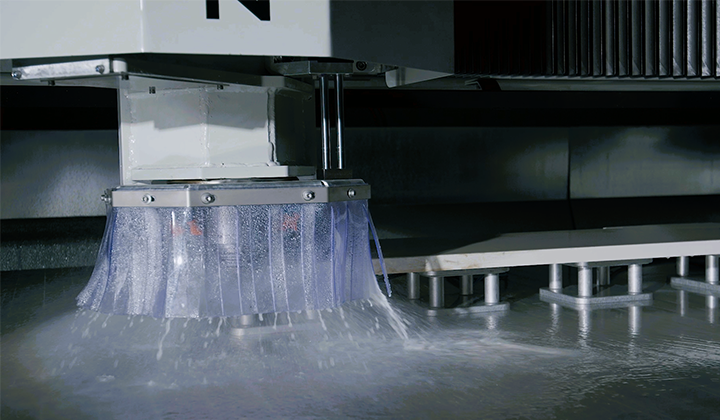

A waterjet machine for stone fabrication, like our M Series, is a cutting-edge tool that uses high-pressure water streams, mixed with abrasive garnet, to cut through stone with precision. This technology is highly beneficial for stone fabrication due to its ability to make intricate and detailed cuts, including non-linear shapes like sinks, arcs, radii, and other complex patterns. Key advantages include minimal material waste, as waterjets eliminate blade overtravel and finish cuts precisely to a defined point. Additionally, waterjet machines can be used to pre-shape non-linear cuts like sinks, arcs, and radii, which increases CNC router capacity by 30%. They are versatile and can handle various types of stone, including ultra-compact, granite, marble, and quartz slabs, making them essential for both standard and custom stone fabrication projects. Investing in a waterjet machine improves cutting accuracy, reduces operational costs, and supports sustainable practices by minimizing waste and maximizing efficiency.

Factors to Consider When Selecting a Machine

Space

Evaluate the dimensions of the machine and ensure it fits comfortably within your workspace. Consider how the machine will integrate with existing equipment and workflows, and ensure it does not obstruct operational areas or limit accessibility.

Investment

Assess your budget, including both the initial purchase price and long-term operational costs. Factor in maintenance, energy consumption, and potential upgrades. Choose a machine that offers the best value and aligns with your financial planning.

Business Needs

Identify your specific production requirements and how the machine will meet them. Consider the machine’s features, capabilities, and capacity relative to your business goals and production volume. Select a machine that supports your current needs while offering scalability for future growth.

By carefully considering these aspects—space, investment, and business needs—you can make an informed decision that enhances operational efficiency and supports your business objectives.

Browse BACA’s Solutions Today

If you’re still not sure which machine is best suited for your application, contact our experts at BACA Systems. We offer a wide range of stone fabrication equipment for all different sizes and types of stone fabricators.

Contact us today to learn more about our products or to get help selecting the right machine for your stone cutting needs. We also offer a Fly to Detroit opportunity to all potential customers, where you’ll learn how to reduce material and labor costs, free up CNC capacity, and improve your profits. We cover all expenses and only ask for your time! Visit our Fly to Detroit page to learn more.