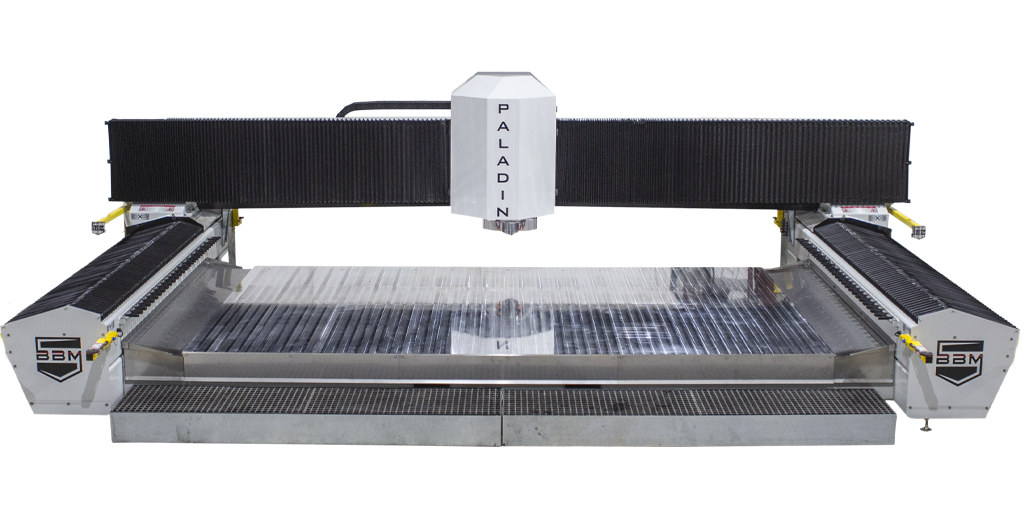

Upgrades are Here!

Get the Latest in Innovative Technologies

At BACA Systems, we're committed to offering the finest cutting, edging, and polishing equipment designed specifically for the stone industry. Our goal is to provide machines of the highest quality, paired with legendary customer service and support.