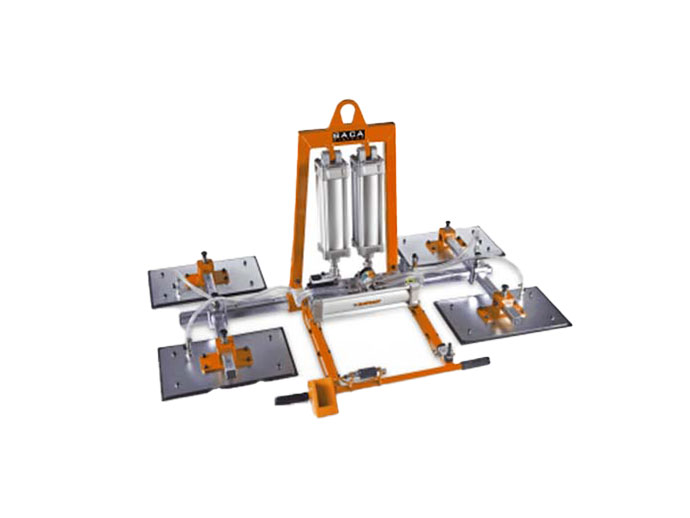

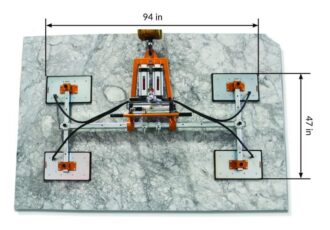

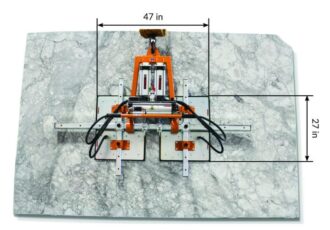

4-Pad Vacuum Lifters

Lifting capacity of 2,200 pounds and 0 to 90 degrees tilting make a vacuum lifter ideal for loading slabs onto machines. Independently turn on/off all 4 vacuum pads to lift all kinds of countertop parts.

Why Choose the 4-Pad Vacuum Lifters