A waterjet machine is a cutting tool that uses a high-pressure stream of water, often mixed with abrasive materials, to slice through a wide range of materials, including metals, stone, and glass. The process involves shooting a concentrated jet of water at extremely high speeds to erode the material and achieve precise cuts. Waterjet machines are known for their ability to make intricate non-linear cuts, such as sinks, arcs, and radii, with exceptional precision.

How Waterjet Stone Cutting Works

In stone fabrication, a waterjet machine operates by directing a high-pressure stream of water, mixed with abrasive garnet, through a fine nozzle to cut through stone with exceptional precision. The waterjet’s intense force effectively erodes the stone, allowing for intricate designs and clean, accurate cuts without generating excessive heat. The waterjet’s versatility ensures that complex stone projects can be completed with high precision and minimal post-processing.

BACA’s Solutions

Robot SawJet 2.0

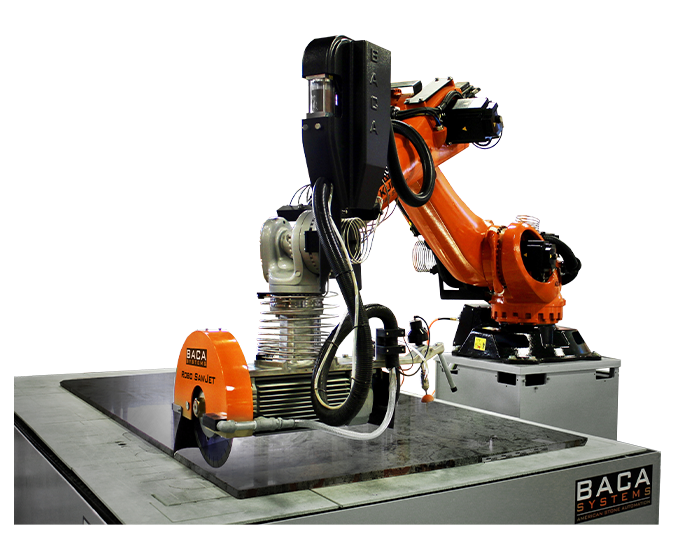

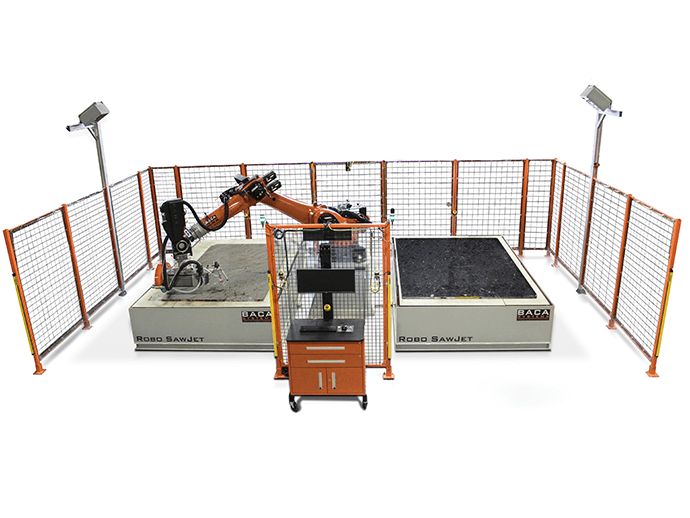

At the heart of the Robo SawJet 2.0 lies a robust foundry-grade KUKA KR 210 robot, equipped with a powerful 26-HP saw motor and a 50-HP H20 waterjet. Renowned for their high reliability and precision accuracy, KUKA robots are the go-to choice for the most demanding applications, including those in automotive plants and aerospace. Unlike custom-built gantry machines, robots require significantly less maintenance. Annual upkeep on the robot involves greasing (2) zerk fittings, and an oil change is recommended at either 10,000 hours of use or after 5 years, whichever comes first. Maintenance for the waterjet on the Robo SawJet is streamlined for simplicity. The waterjet lines are easily accessible on the exterior of the robot, eliminating the need to navigate through conventional cat tracks as seen with some competitors. This user-friendly design is complemented by BACA’s Waterjet Made Easy exchange program.

The Revolutionary M Series Robo SawJet

The Robo SawJet M Series stands out for its exceptional mitering capabilities, combining the precision of a saw blade with the versatility of a waterjet for a complete processing solution. This integration makes it ideal for a variety of applications, including precision mitering of inside corners (L-shapes), integrated sinks, and custom countertop work. While the saw blade efficiently handles straight cuts at higher speeds and lower costs, the waterjet is employed for complex, non-linear cuts, like sinks and arcs. The real advantage of the M Series is its optimized use of the saw blade, reserving the waterjet for specialized tasks to reduce material waste and eliminate blade overtravel.

Features & Specifications At a Glance for the Robo SawJet 2.0 & the Robo SawJet M Series

Here is a quick list of the features and specs to make it easier to skim through what the Robo Sawjet and Robo SawJet M Series have to offer. Features for both waterjet cutting machines include the following:

• Fully sealed KUKA KR210 Robot

• 26-HP saw motor

• 16” saw blade

• Tamper-proof nozzles with 12 GPM of water, focused on cooling

• Variable frequency drive (adjusting the RPM of the saw blade)

• Easy-to-remove saw guard

• H2O Jet waterjet pumps designed for 24/7 usage

• H2O Jet nozzle with Integral Diamond Eductor

• Both systems are upgradeable from Single to Dual Table for a fraction of the cost of a new machine

A Solution for Every Stone Fabricator

BACA Systems offers a comprehensive lineup of machinery tailored for stone fabricators of all sizes and types. Our range includes: SawJets, which combine saw and waterjet capabilities for versatile cutting; 5-Axis CNC Saws for precise and complex miter cuts; dedicated Miter Saws for consistent miter cuts; and CNC Routers for detailed edge shaping and polishing. We also provide Sink CNC Routers, Line Polishers for edge profiling and polishing, Water Filtration Systems for recycling and maintaining water quality, and Material Storage Systems for safe and condensed slab storage. This extensive selection ensures that fabricators have access to the latest technology to enhance their fabrication processes. Click here to view all BACA’s machinery options.